Businesses that deal with temperature-sensitive products rely on cold room doors for maintaining the separation between two temperature-controlled spaces. Businesses that need refrigeration may include:

may include:

- Meat & Poultry Processing Plants

- Fresh Produce Suppliers

- Pharmaceutical Facilities

- Cold Storage Warehouses

- Grocery Distribution

Finding freezer and cooler doors that provide the ideal R-value and high-speed cycle times can prove to be a challenge that most facility managers may find difficult to overcome.

Hundreds of different designs are available on the market, each design offering something unique. However, not every door offers the same features or dependability. Choosing the wrong door design can lead to loss of environmental control, declining productivity, facility damage, and safety issues.

Important Factors

Take a look at five main factors customers should consider when choosing quality cold room doors:

-

Environmental Control

Environmental control is critical to cold storage. Loss of temperatures can compromise product quality. Food safety is on high alert when environmental control is lost in a cold storage warehouse or processing plant. These three critical factors need to be investigated in order to apply the proper cooler or freezer door:

-

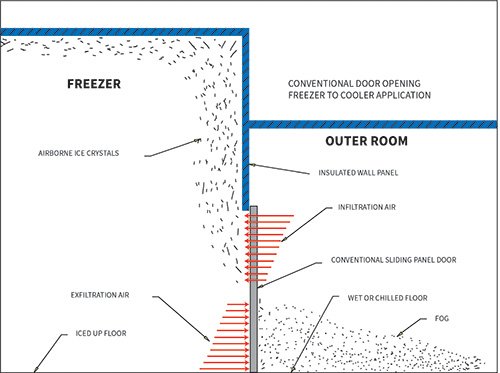

- Convection is the transfer of heat from one space to another by movement of liquids or gases. In cold storage facilities, warm air from outside the cooler or freezer meets the colder air through poorly sealed openings or open doorways. In freezer applications, the moisture in the warm air crystallizes, which forms ice and frost buildup inside the freezer. In cooler applications, the moisture in the warm air condenses creating droplets of water on the walls, slippery floors, and fog. Utilizing doors with tight seals and faster opening speeds help reduce the transfer of heat.

- Conduction is the transfer of heat through one medium to another of different densities. Lower R-value walls and doors allow heat to travel easier through the materials. When the two different temperatures collide, the warmer air condenses and sticks to the walls and doors. Doors that are poorly insulated require costly heat and blower systems to minimize the moisture buildup. Choosing high-performance doors with higher R-values mitigates the heat transfer through the material and lowers operational costs.

- Door Opening Usage can have a major impact on maintaining proper temperatures. Doors that are opening and closing constantly throughout the day make it difficult to avoid convectional heat loss. Understanding the amount of opening cycles you have per day ensures the proper door is selected for your application.

Inspecting these elements closely and assessing their impact will help you make the best cold room door decision for your cooler or freezer.

-

Energy and Efficiency

Choosing the right cooler door can vastly improve your facility’s efficiency. For instance, a fast-operating door enables the product to move through the opening quickly. This reduces the amount of time the door is open, cutting down the transfer of energy, as mentioned above. In addition, high speed doors will improve the traffic flow through the facility. A proper analysis of the facility’s efficiency and operation issues can lead to selecting the right door.

-

Safety

You have heard it before; safety is no accident. Increased safety at these busy facilities is at the core of any cold storage facility. Whether you are trying to maintain optimal temperatures,

eliminate ice and frost buildup, or avoid slippery floors, proper door selection can play a huge part. Additionally, high traffic openings in cold storage facilities will demand higher visibility than spaces with lower traffic. Selecting high speed doors that include various safety features i.e., audible alarms, LED light indicators, photo eyes, safety reversing edges, and light curtains, will create a safe operation.

-

Activation

When doors fail to open, it is usually the door that takes the blame, when in reality it is the activation controls. Choosing the right door activation i.e., motion detectors, floor loops, pull cords, or push buttons, cannot be overlooked. Installing the proper activation can improve productivity, downtime due to damage, and unwanted opening and closing of the door. When deciding on the best activation for your door opening, be sure to analyze the physical attributes of the opening, traffic flow through the facility, and understand the various activation devices available.

-

The Manufacturer

The door manufacturer you choose in the end should offer a complete product portfolio that provides solutions for multiple applications. Not doing so creates a challenge in sourcing parts, providing service, and warranty claims. In addition, you could save money upfront by bundling your purchase. Here are some tips for selecting a door manufacturer that is right for you:

-

- Have them provide multiple references of their customers in the area.

- Request a demo or visit a site where you can see the product in action.

- See if the company can arrange a factory visit.

- Ask about the door’s life expectancy and preventative maintenance required.

- Understand what the wear parts are and avoid complicated products with a lot of moving parts.

- Inquire about written warranties. (Make sure to read the small print)

Open Up to What’s Possible with ASI Doors

Selecting the right door doesn’t have to be difficult. ASI doors is a leading manufacturer and provider of energy-efficient and high-performance door solutions for a range of applications. Contact us today for details on how ASI doors can help cut energy costs for your cold storage and refrigeration operations.