Since the introduction of the COVID-19 virus, manufacturers of biopharmaceutical products and medical devices have had to ramp up their efforts to help overcome the virus. The pandemic has led to a severe disruption of supply chains for raw materials and products from suppliers and manufacturers. This was against the backdrop of a massive increase in demand for critical pieces of equipment such as testing kits, PPEs, and ventilators. New construction and renovations of these facilities have skyrocketed which has created opportunities and challenges for companies that supply equipment and services to these facilities.

Since the introduction of the COVID-19 virus, manufacturers of biopharmaceutical products and medical devices have had to ramp up their efforts to help overcome the virus. The pandemic has led to a severe disruption of supply chains for raw materials and products from suppliers and manufacturers. This was against the backdrop of a massive increase in demand for critical pieces of equipment such as testing kits, PPEs, and ventilators. New construction and renovations of these facilities have skyrocketed which has created opportunities and challenges for companies that supply equipment and services to these facilities.

Most biopharmaceutical products and medical devices must be manufactured in a controlled environment or a cleanroom, free from contamination. Cleanrooms are typically used for manufacturing pharmaceutical products, electronics, and medical equipment. To help mitigate the contamination, it is critical that you have the right door. Cleanroom doors must meet industry regulations set by agencies, such as the FDA. Combining specialized hardware, easy to clean materials, and advanced locking technologies, cleanroom doors offer a controlled space, free of dust, aerosol particles, and airborne microbes.

Having a flexible cleanroom door system enables project engineers to incorporate vision panels on doors, touchless activation, magnetic locks, and interlocking systems. The most important feature a cleanroom door system can have to prevent contamination is an interlocking system.

What is an interlock?

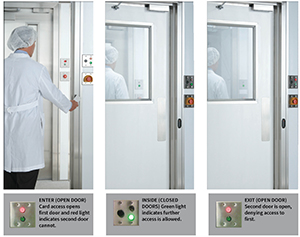

An interlock sometimes referred to as an “airlock,” can take many forms. In its simplest form, an interlock comprises two doors, each opening into a separate space, with an airspace between them. The airspace will be referred to as airlock where appropriate in this article. The functional concept of an interlock is to prevent two doors from being opened at the same time, therefore preventing air from passing from one space directly into the other. Interlocks are typically used in cleanroom environments and manufacturing areas to preserve air quality and prevent outside airborne particulates from entering process areas. Common areas in cleanroom and production environments using interlocks are personnel entrances and exits, gowning and degowning areas, and material transfer airlocks.

An interlock sometimes referred to as an “airlock,” can take many forms. In its simplest form, an interlock comprises two doors, each opening into a separate space, with an airspace between them. The airspace will be referred to as airlock where appropriate in this article. The functional concept of an interlock is to prevent two doors from being opened at the same time, therefore preventing air from passing from one space directly into the other. Interlocks are typically used in cleanroom environments and manufacturing areas to preserve air quality and prevent outside airborne particulates from entering process areas. Common areas in cleanroom and production environments using interlocks are personnel entrances and exits, gowning and degowning areas, and material transfer airlocks.

Soft Interlocks

The simplest, albeit least effective, type of interlock is based purely on protocol. This “soft” interlock can be overridden by a person who accidentally or intentionally breaches protocol and violates the air space. In the most basic soft interlock, each door leading into the airlock has a vision panel (window). A person wishing to enter from either side looks through the window to see whether the opposite door is open or closed. If the opposite door is closed, the protocol allows that person to enter the airlock. If the opposite door is open, the person waits until it is closed before entering.

Adding a position switch to each door that is connected to a controller with outputs to a visual and/or audible indicator is an alternative arrangement. When one door is open, a lighted sign will activate above the opposite door stating, “Do not enter,” or announcing a similar warning. Another method is to use red and green lights instead of a lighted sign. With both doors in the closed position, a green light would indicate that either door can be opened. Once one door is opened, the light on the opposite door turns red, indicating that the airlock cannot be entered from that side. If an audible alarm is added, any personnel violating the protocol by ignoring the lighted indicator and opening a door in breach of protocol will cause the buzzer or siren to sound until one door is closed.

Another simple type of interlock adds automation into the equation. In this case, if an automated door is opened, a position switch will activate, causing the controller to interrupt the activation signal to the opposite door, thus preventing automatic operation. The same go/no-go indicators mentioned previously would also apply to this situation.

Hard Interlocks

Hard interlocks add a locking mechanism into the system to create another level of insurance to prevent violation of protocol. The system requires that each door be equipped with a position switch and an electrically controlled locking device. In clean environments, these devices are generally electromagnetic devices commonly referred to as “mag-locks.” In this system, both doors are normally unlocked. When one door is opened, the position switch triggers an input signal to the interlock controller, which sends a signal to activate the locking device of the opposite door. The second door remains locked until the first door is closed. Once the first door is closed, the locking signal to the second door is dropped, and both doors return to normally unlocked status until the next input is received at the controller.

Hard interlocks add a locking mechanism into the system to create another level of insurance to prevent violation of protocol. The system requires that each door be equipped with a position switch and an electrically controlled locking device. In clean environments, these devices are generally electromagnetic devices commonly referred to as “mag-locks.” In this system, both doors are normally unlocked. When one door is opened, the position switch triggers an input signal to the interlock controller, which sends a signal to activate the locking device of the opposite door. The second door remains locked until the first door is closed. Once the first door is closed, the locking signal to the second door is dropped, and both doors return to normally unlocked status until the next input is received at the controller.

The same go/no-go indicators previously described for soft interlocking can be added to a hard interlock system for added communication capability. This is often valuable for employees to understand why a door is locked and they cannot enter the space.

Operation in an Emergency

With any hard interlock system, life safety and emergency ingress and egress issues must be considered. At a minimum, the airlock should include an emergency release device to prevent anyone from being trapped inside. It is also common to provide a means of interfacing the facility’s building management system with the interlock controller. This would ensure that all doors are unlocked in the event of a fire alarm, sprinkler flow, or other user-defined event.

Integrating with Equipment

Hard interlocks are also available for integration in systems with automatic door operators. The functionality remains, but an interrupt signal output is added to the automatic door operator, preventing it from opening a locked door. In addition to simple two-door interlocks, security interlocks, multiple door interlocks, and equipment or process interlocks are solutions to consider. With pharmaceutical companies that develop, manufacture, and market COVID-19 vaccines and medicines, they require an interlock system that provides increased security and insurance.

Conclusion